Manufacture of steel.

Steel is made past times diverse methods but (a) Bessemer process, too (b) Open hearth process are of import too normally used.

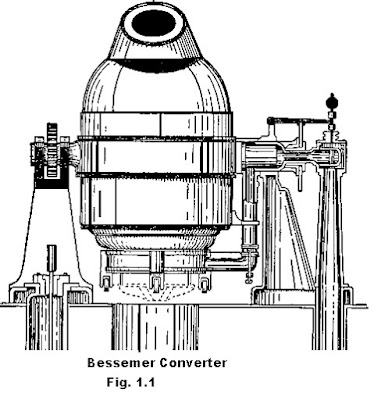

Bessemer Process.

This procedure is carried out inwards a pear-shaped furnace called Bessemer converter (Figure 1.1) The converter is made of steel plates too lined amongst silicious cloth (sand too modest amount of clay) or bricks. Influenza A virus subtype H5N1 release of holes are introduce at the bottom of the converter to acknowledge a boom of air.

In the Bessemer process almost 10 tons of molten pig-iron are come across the converter. When the converter has been charged too the boom of air is turned on, the temperature rises due to oestrus envolved during oxidation too combustion of impurities. Carbon is oxidation to CO, which burns at the oral cavity of the converter. The carbon monoxide open fire gives an indication for the completion of the process. When carbon monoxide open fire subsides, calculated amount of spiegeleisen (carbon too manganese or other metals) is added too the boom turned on ane time again for a few minutes.

If Bessemer converter is lined amongst silica, it is called the Acid Bessemer process. Influenza A virus subtype H5N1 Basic Bessemer Process involves lining of dolomite or lime or magnesia too is used to convert pig-iron (Containing higher proportions of S, P too silicon) into steel.

The Bessemer process has revolutionized the manufacture of steel because it is cheaper less fourth dimension consuming.

Open Hearth procedure (Siemens Martin Method)

This method is right away widely used for the manufacture of steel. the open-hearth furnace is shown inwards figure 18.3 the furnace is charged amongst a mixture of pig-iron, chip atomic release 26 too haematite ore costless from carbon. The mixture is melted inwards a shallow rectangular trough or hearth. The furnace is heated past times producer gas. The direction of the burning gases is reversed afterwards almost ½ hour. In this way the oestrus of the flue gases is utilized inwards warming upwards chambers through which air too unburnt gases are passed. Thus this furnace is called Siemens’ regenerative furnace.

The atomic release 26 ore too chip atomic release 26 help inwards oxidising impurities. Carbon is oxidised to CO which goes off. Impurities such every bit P too due south from corresponding oxides inside 8- 12 hours.

The atomic release 26 ore too chip atomic release 26 help inwards oxidising impurities. Carbon is oxidised to CO which goes off. Impurities such every bit P too due south from corresponding oxides inside 8- 12 hours.

Fe2O3 and basic oxides (CaO from limestone added along amongst the accuse inwards the furnace) human activeness every bit flux too from slag amongst oxides of phosphorus too silicon. If sulphur too phosphorus are introduce inwards negligibly modest quantities, the furnace may move lined amongst SiO2.

When the required carbon content is reached during the process, the molten steel is removed. Small quantities of other metals such every bit Mn, Cr or Ni are added to cook special type of steel .

The steel obtained past times open-hearth procedure is used for making heavy rails, guns, girders too ships, etc.

Advantages of Open-Hearth Process over Bessemer Process.

Scrap atomic release 26 too the atomic release 26 ore tin move straight converted into steel past times open-hearth cess.

The external source of oestrus used inwards open-hearth procedure is to a greater extent than convenient too temperature tin move accurately controlled.

The composition of steel is to a greater extent than uniform too accurate inwards open-hearth procedure too tin move easily controlled.

Low degree cast atomic release 26 tin move used inwards this process.

Steel obtained past times open-hearth procedure is of high degree too of proficient quality.

Electrical Process.

Electric furnaces, ofttimes of are type, are used to larn high character steels. As no fuel is used, at that spot are less chances of contamination past times impurities, Electrical procedure are pop for preparing proficient character steel, peculiarly when electrical ability is cheap. Influenza A virus subtype H5N1 release of steel alloys are made past times these met

Various procedure based upon oestrus handling give steel of dissimilar quantities Annealing is a procedure inwards which steel is heated to redness too allowed to cool tardily quenching refers to the procedure inwards which steel is heated to redness too cooled all of a precipitous inwards H2O petroleum tempering way heated steel at constant temperature for or too so fourth dimension earlier cooling.

Alloy Steel.

Many useful alloys of steel are manufactured past times adding metals inwards modest amounts. Some of import alloys of such type are :

Stainless steel.

(Fe = 73 - 79%, Cr = xiv - 18%, Ni = vii - 9%) is a corrosion resistant alloy used inwards cutlery too industry.

Invar.

(Fe = 64%, Ni = 36%) has depression coefficient of expansion too used inwards pendulum rods, meter scales, etc.

Silicon Steel.

(Fe = 95 - 99%, Si = 1 - 5%) is difficult too highly magnetic too therefore used inwards magnets.

No comments:

Post a Comment